Bringing process engineering, project management, quality, and regulatory expertise to all we do

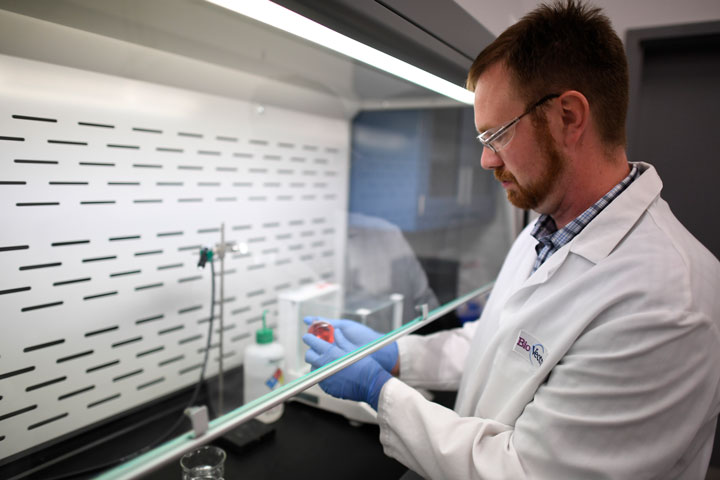

For over fifty years, BIOVECTRA has been dedicated to producing quality products and effectively managing client projects. However, as our clients’ needs have become more demanding, we’ve found new ways to partner to rise to the challenges.

Our teams work to stay ahead of evolving quality requirements and the leading global agencies’ regulatory demands. Specialized quality teams carefully align to support our products as they move through the development process and ultimately to the manufacturing floor.

Upon onboarding of your project, our process engineering group works hand-in-hand with the project team to proactively address any challenges around equipment and room set-up. Additionally, BIOVECTRA has long been dedicated to effective project management to improve our clients’ experience and keep programs on track. We continue to invest heavily in project management and technology tools, increasing efficiency and advancing speed-to-market initiatives.